product model: G7000

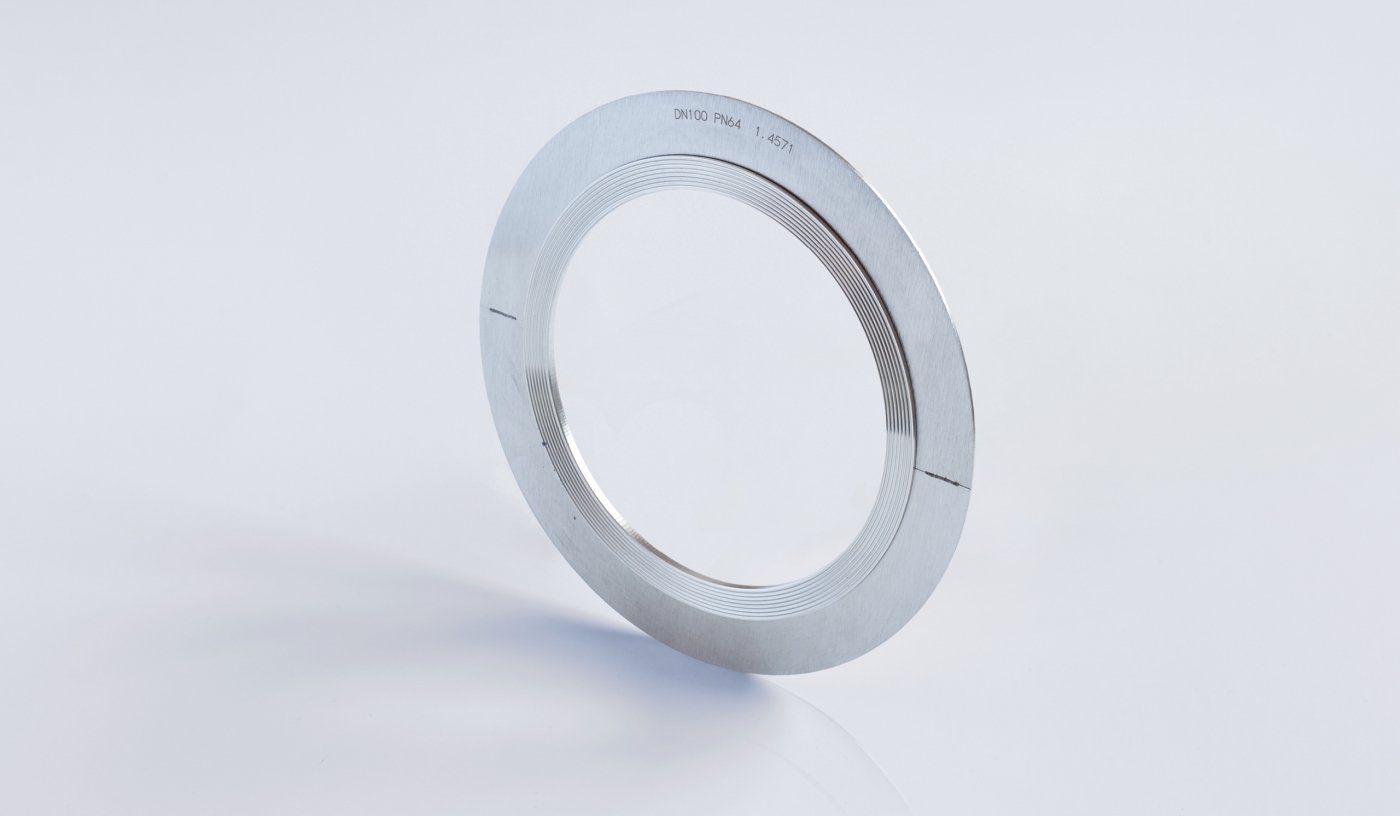

Product Description:

Metal toothed pad (Kammprofile Gasket), the general use of precision lathe in the metal stainless steel flat gasket on both sides of the processing into concentric groove, according to different media, you can choose flexible graphite, PTFE, no asbestos board or some other soft metal, paste on the two sides of the gasket. It can also be used directly without a sealing layer, and can achieve a good sealing effect, but it is easy to cause loss to the surface of the flange in high-pressure situations.

Product Application:

Toothed combination gaskets are mainly used in petroleum, chemical, metallurgy, electric power, shipbuilding, machinery and other industries, high pressure and high temperature pressure vessels, heat exchangers, condensers and pipe flanges. The use of low preload is the first gasket. The soft surface sealing layer avoids direct metal-to-metal contact, and can be reliably and tightly combined to protect the metal flange from damage, even in Extremely high load. The tooth-shaped combination pad is especially suitable for high temperature, high pressure, and alternating working conditions. It is an ideal substitute for the traditional metal coated gasket in the flange connection of heat exchanger, container and reaction kettle. Pressure range: 6.4 ~ 25Mpa

|

Structure form and code of tooth-shaped combined gasket and flange type:

|

|

basic type

|

Code

|

applicable flange sealing surface

|

thickness(mm)

|

|

sealing body

|

Paste Layer (Single-sided)

|

|

basic type

|

ZD-1900A

|

Mortise and groove surfaces, concave and convex surfaces, flat surfaces and groove surfaces

|

3,4,5

|

0.5-1.0

|

|

with outer ring (fixed)

|

ZD-1901C

|

Plane or Convex

|

3,4,5

|

0.5-1.0

|

|

with outer ring (active)

|

ZD-1902C

|

Plane or Convex

|

3,4,5

|

0.5-1.0

|

|

with earrings

|

ZD-1903C

|

Plane or Convex

|

3,4,5

|

0.5-1.0

|

|

|

Gasket Covering Material and Technical Parameters

|

|

material

|

Identification code

|

temperature °C

|

Maximum working pressure

|

Applicable medium

|

compression rate%

|

rebound rate%

|

stress relaxation rate%

|

|

expanded graphite

|

F.G.

|

-220-550

|

250 BAR

|

Corrosive medium

|

18-30

|

≥ 17

|

≤ 18

|

|

Teflon

|

PTFE

|

-100-200

|

100 BAR

|

Corrosive medium

|

18-30

|

≥ 15

|

≤ 13

|

|

expanded polytetrafluoroethylene

|

EPTFE

|

-100-260

|

200 BAR

|

Corrosive medium

|

25-35

|

≥ 25

|

≤ 13

|

|

non-asbestos material

|

NA

|

-100-350

|

100 BAR

|

General airtightness

|

18-30

|

≥ 19

|

≤ 28

|

|

Cloud mother

|

MICA

|

-150-800

|

100 BAR

|

very high temperature

|

18-30

|

≥ 19

|

|

|

ceramic fiber

|

CER

|

-200-1090

|

100 BAR

|

ultra-high temperature

|

18-40

|

≥ 19

|

|

tooth combination gasket metal skeleton material selection:

|

Material Name

|

Abbreviations Mark

|

hardness(HB)

|

limit temperature(°C)

|

|

carbon steel (Carbon steel)

|

CRS

|

120

|

-40 ~ +540

|

|

304 stainless steel

|

304

|

130~180

|

-195 ~ +760

|

|

304L stainless steel

|

304L

|

130~180

|

-195 ~ +760

|

|

316L stainless steel

|

316L

|

130~180

|

-100 ~ +760

|

|

317L stainless steel

|

317L

|

|

-100 ~ +760

|

|

321 stainless steel

|

321

|

130~190

|

-195 ~ +760

|

|

347 stainless steel

|

321

|

|

-185 ~ +760

|

|

20CB-3(ALLOY 20)

|

A- 20

|

|

-185 ~ +1090

|

|

HASTELLOY-B2

|

HAST B

|

215

|

-185 ~ +1090

|

|

HASTELLOY-C276

|

HAST C

|

|

-185 ~ +1090

|

|

INCOLOY-800

|

IN 800

|

|

-100 ~ +870

|

|

INCOLOY-825

|

IN 825

|

|

-100 ~ +870

|

|

INCONEL-600

|

INC 600

|

150

|

-100 ~ +1090

|

|

INCONEL-625

|

INC 625

|

|

-100 ~ +1090

|

|

INCONEL-X750

|

INX

|

|

-100 ~ +1090

|

|

MONEL-400

|

MON

|

150

|

-130 ~ +820

|

|

NICKEL-200 (Nickel)

|

NI

|

|

-195 ~ +760

|

|

TITANIUM (Titanium)

|

TI

|

215

|

-195 ~ +1090

|

Dimensional limit deviation of toothed combination gasket:

|

Inner diameter of tooth-shaped seal bodyD1

|

inner diameter of tooth sealD2

|

Outer ring outer diameterD3

|

thicknessT

|

|

+1.5

0

|

0

-0.75

|

+1.5

0

|

+0.25

0

|

toothed pad performance parameters:

|

Gasket Coefficient

|

m=4.25

|

|

Gasket use pressure

|

≤ 25MPa

|

|

Gasket use temperature

|

-196 ℃-650 ℃ (not higher than 450 ℃ in oxidizing medium)

|

|

Minimum preload specific pressure of gasket

|

y=50MPa

|

※Customers choose different skeleton materials and adhesive layers according to different operating conditions. Generally, the performance of the adhesive layer is the main reference, such as graphite for high temperature resistance and tetrafluoro for corrosion resistance..

|

|

metal toothed composite gaskets:

1.metal tooth combination gaskets are:ASME B 16.5, BS1560, ASME B 16.47, BS EN1092, DIN2697, JISandNF.

2.domestic standards areJB/T 88-1994Standard for mechanical part of metal toothed gaskets for pipe flanges

HB 6474-1990|toothed washerDepartment of Aerospace Standards

HG20611-2009Steel Pipe Flange Toothed Composite Gasket Chemical Department European System

HG20632-2009Steel Pipe Flange Toothed Composite Gasket Chemical Department Inter-American System

more standards or requirements please contact us

|